Our methods for your automation projects

The V-life cycle model to represent the phases of your project

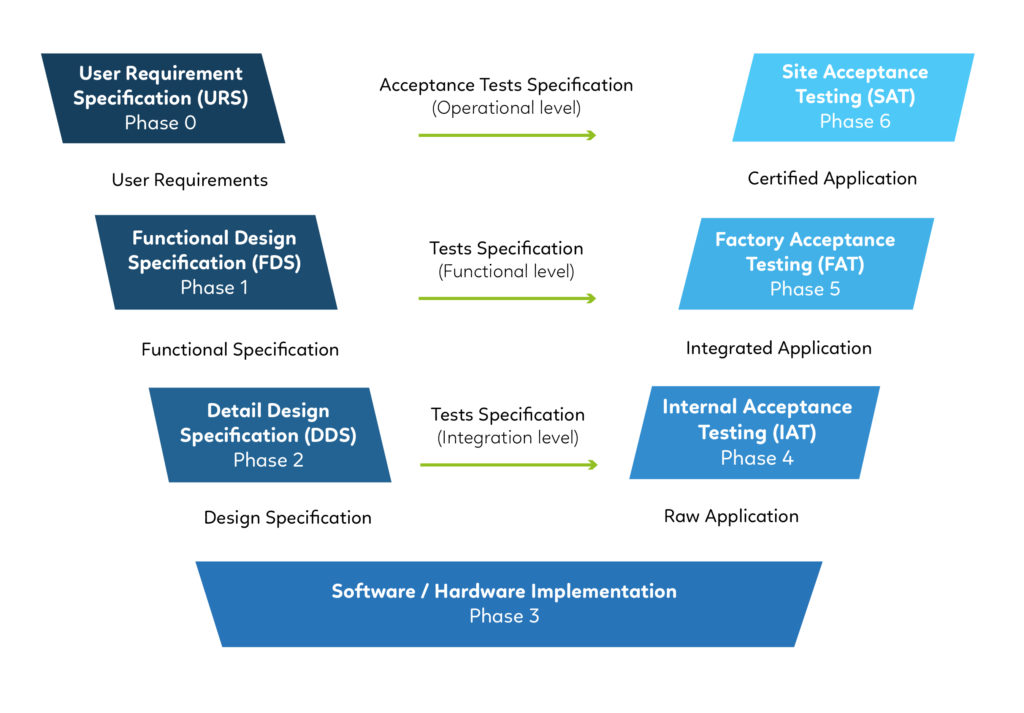

CORIOLIS adopts the V-life cycle model to represent the different phases of automation projects.

The left part, descending, corresponds to the actual development whereas the right part, ascending and symmetrical, is related to the tests and to the commissioning.

Each phase is based on well-defined specifications.

Phase 0 (needs analysis)

is preliminary to the project; our technical and commercial proposal will rely on the expression of the customer’s needs through his user requirements specification.

Phase 1 (functional analysis)

leads to a specification folder reflecting the requirements in terms of automation features; it is the critical phase of the cycle which implies an extensive dialogue with the customer who will have to validate the latest version of the drafted document.

Phase 2 (design)

consists in converting the functional specifications into a design description including the definition of the hardware and software used, as well as the description of the software developed.

Phase 3 (implementation)

consists mainly in keying the source codes using specialized editors, configuring the various hardware and software used and linking the whole project.

Phase 4 (integration testing)

can mix many levels depending on the project complexity: basic checking of standard components, testing the links between components in sections, between sections in units, ... These tests are carried out by the developer who uses simulation software integrated into development workshops on the basis of the integration test book that may have been produced during the design phase.

Phase 5 (functional testing)

is set with the customer on a platform whose configuration is as close as possible to the site, realistically simulating equipment or processes using appropriate software. Test reports shall be approved by the customer.

Phase 6 (commissioning)

is done on site with a certified development. We can therefore focus on the specific problems of commissioning: mechanics, electricity, adjustment of operational parameters (rates, specific settings, ...)

Phase 7 (optimization)

allows modifications or improvements on problems seen during commissioning or during the production phase.